OLMEC oil-oil boosters with working pressures up to 4.000 bar, low pressure side with single-acting or double-acting operation can be used as a pressure generator only on single-acting circuits. The hydrulic circuit volume should utilise the working only up to 70-75% so as to have some reserve left. They can provide their volume, in the fastest times in the movement being in uenced only by the oil volumetric ow using and hydraulic application friction. This may cause malfunctions in clamping elements where the maximum volume ow is limited (swing clamps, work supports). In those cases a ow control valve must be provided on the oil side.

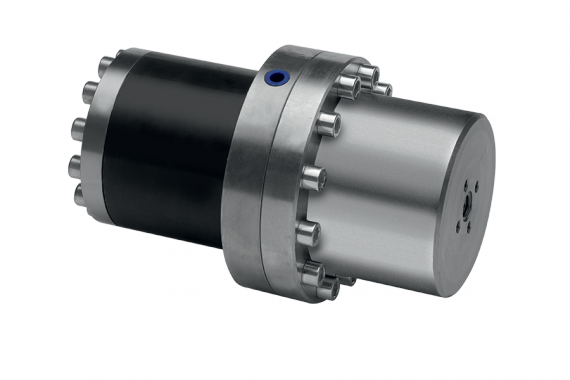

We have 2 types of booster, which differ in design concept and pressures.

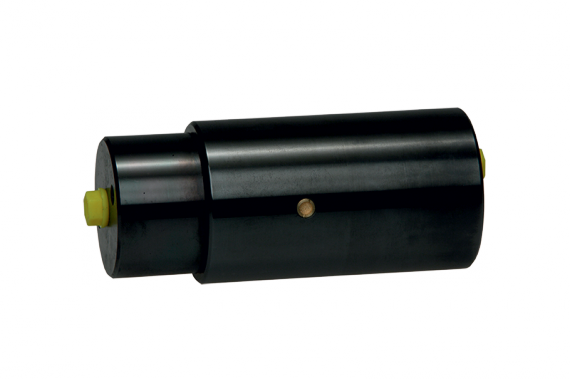

A line for pressures up to 400 bar with internal check valve and unique oil ow in the circuit, ideal for clamping equipment and hydraulic drives with little volumes.

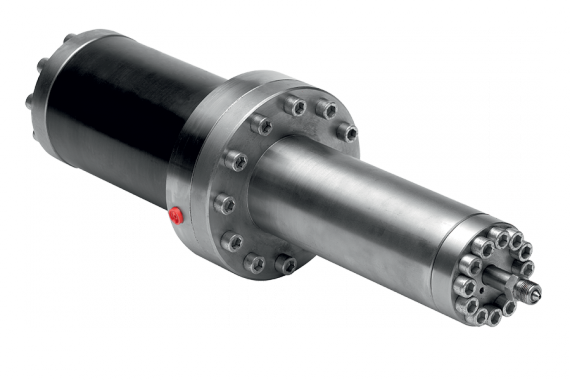

Another line for pressure up to 4.000 bar and volumes achievable depending on the requirements of the circuit, with all the accessories necessary for the pressure and position control. Have the possibility to work with two different fluids between the low pressure side and high pressure side or with the same uid in the system and are capable of delivering their volume with very high speed (up to 500mm./sec.) in function of ilow pressure side inlet flow rate.

In order to ensure that the boosters give satisfactory service users are advised to follow the instructions in the user manuals which are always supplied, and to bear in mind a few fundamental rules:

- oil temperature 0°C + 40°C;

- ambient temperature +5°C + 40°C;

- hydraulic fluid viscosity 3°E / 50°C - ISO 32 / 46.

- filtration 10 micron nominal, maximum 19/16 according to ISO 4406

Italiano

Italiano  English

English